Does annealing temperature has any effect on TZM alloy mchanical properties ?

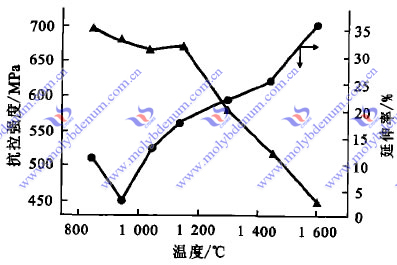

Since preparation of TZM alloy(titanium zirconium molybdenum) extrusion process produces great stress, the stress by changing the annealing temperature is changed to the hardness and toughness properties of alloy to improve its mechanical processing performance, so that in practical applications with good performance. Fig.1 shows the elongation of the alloy, tensile strength and the annealing temperature curve.

As can be seen from the figure, as the annealing temperature, elongation increased hardening waning. Fig.1 can be drawn from both the 850 ~ 1 050 ℃ range, as the annealing temperature, maintaining a low elongation and may vary slightly, mainly because in this range, TZM Alloy has not many changes, still processing state fibrous tissue. In a wide temperature range (850 ~ 1150 ℃), TZM alloy in response to the initial stage, the macroscopic stress after heating temperature although most can be removed, and the microscopic residual stress remains.

Pic. Tensile Strength and Elongation Curve

In 1150 ~ 1600 ℃, with the annealing temperature, elongation increases. In the recovery phase, strength, ductility and other mechanical properties of little change, but in the recrystallization phase, significantly decreased strength, ductility was significantly increased, when the grain growth, the intensity continued to decline in the crystal grain coarsening of plastic is not very serious still continues to rise trend, grain coarsening serious, plasticity also declined.

Reply TZM alloy(titanium zirconium molybdenum) complete recrystallization two grain growth process, from long fibrous tissue becomes equiaxed grains, while TZM alloy greatly improved toughness, elongation, even up to 37%. From the relationship between tensile strength and the annealing temperature curve, with the annealing temperature, TZM alloy tensile strength decreased.

High strength at low temperatures due to enhanced carbide phase particles after deformation processed into a fibrous, distributed in the grain boundaries and inside. After high temperature annealing of these enhancements and uniform dispersed phase in the matrix, so high temperature performance of low intensity, good plasticity. 2 from the stretching temperature curve can be seen, 950 ℃ the elongation rate is almost zero.

If you have any interest in our TZM alloy((titanium zirconium molybdenum) or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.