Does lanthanum has any effect on TZC alloy room temperature mechanical properties?

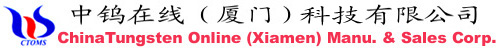

Pic.1 is a temperature TZC alloy compression performance and lanthanum (La) the content of the curve, can be seen, with lanthanum (La) content increases, the ultimate compressive strength increases, and the relative compression rate of about 0.5% lanthanum (La ) Department has a maximum value of more than 0.5% lanthanum (La), the relative rate of pressure downward trend series.

Pic.1 The Relationship Between Room Temperature Ccompression Performance and La Content

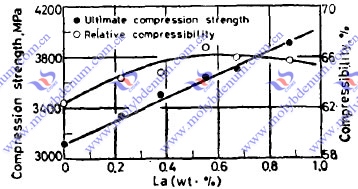

Tensile test results are basically consistent with the results of compression tests at room temperature, room temperature tensile alloy Pic.2 SEM fracture topography image, which can be seen, there is no plus lanthanum (La) the TZC alloy is very brittle, stretching produces an almost 100% intergranular fracture, while adding lanthanum (La) amount of alloy, its brittleness significantly improved, showing transgranular fracture and intergranular mixed state. Impact test results also show that the amount of lanthanum (La) can reduce the PM-TZC alloy DBTT, and to increase the impact toughness of lanthanum (La) is too high only increased DBTT.

Pic.2 Room Temperature Tensile Fracture Scanning Electron Micrograph

(a)TZC-0(0.00%La)x2500,(b)TZC-9(0.65%La)x2500,

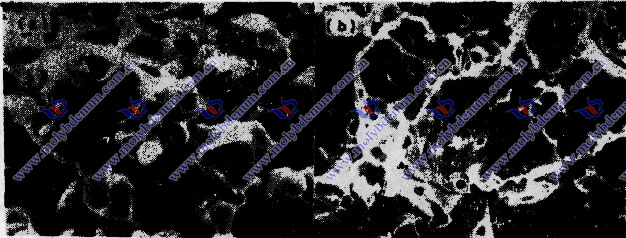

Pic.3 is a three alloys toughness and shock temperature curves, no lanthanum (La) alloy DBTT is about 320 ℃, containing 0.38% lanthanum (La) TZC alloy DBTT is about 270 ℃, while containing 0.68% lanthanum (La) alloys DBTT is about 370 ℃.

Pic.3 Impact Toughness and Shock Temperature

From the above results can be drawn, without lanthanum (La) of the PM-TZC alloy brittle at room temperature, there is a serious; fitness t, lanthanum (La) can be improved brittleness TZC alloys, but lanthanum (La) is too high and the brittle reproduction.

No lanthanum (La) alloy brittle at room temperature is mainly carbon and oxygen in the grain boundary segregation caused by a large number of such atomic impurity segregation at the grain boundary binding force decrease, when subjected to external force, cracks in the grain boundary Department nucleation along grain boundaries, leading to intergranular brittle fracture.

Lanthanum (La) is added so that the carbon and oxygen segregation reduced, enhanced binding force of the grain boundary, the crack propagation path is partially transferred to the grain interior, resulting in transgranular and intergranular fracture mix, increasing the toughness . However, lanthanum (La) is too high, along the grain boundary of the second phase particles too, there again the alloy brittle.

If you have any interest in our TZC alloy or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.