Maximum use of molybdenum steel and non-ferrous alloys as additive, including a gas turbine engine with heat-resistant super alloys. Molybdenum and other refractory metals as with anti-corrosion ability, heavy, thermal expansion coefficient, high temperature strength and high hardness important features, its use is still expanding.

Molybdenum and molybdenum alloy in high temperature applications are as follows:

Hot isostatic pressing equipment

Fact that, subjected to the sintering or casting pressure and 2000 ℃ 200MN/m2 the combined effect of high temperature, can greatly improve the organization and performance. Is known, this is the process of hot isostatic pressing (HIP). HIP device can be used in a number of sections or large molybdenum TZM alloy heat shield. Further, in some HIP apparatus, the lower the pressure vessel with a large ventilation fans to accelerate the gas flow. Fan rotor spin axis and the balance are made with TZM alloy.

High machining performance

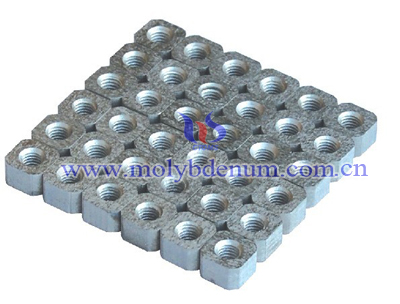

Molybdenum and molybdenum alloy high temperature mechanical properties that make them widely used in a variety of thermal processing of several, for example, TZM alloy forging hammers used for processing other refractory metals. The TZM alloy extruded brass mold with long life, while other materials can not meet these requirements. Also in the use of isothermal forging TZM alloy as a mold material, it can be difficult using traditional methods forging machining of titanium and its alloys and nickel-base superalloy. Compressor disk and the rotor is through this way processing out of key parts, the processing temperature of about 1130 ℃. If during forging tools and machined parts to keep the temperature constant, then we can achieve its optimum mechanical properties.

It is believed that, TZM alloy having the desired strength and resistance to thermal creep, is the only material to meet this purpose. Diameter die used 76omm, weighing more than 5t, in order to prevent oxidation, the mold must be placed in the appropriate protective atmosphere, usually nitrogen.

Molten glass electrode

In addition to the relatively high cost, the use of electrical energy to melt the glass in the last 30 years has become increasingly important, because it has many advantages over fossil fuels. Compared with burning oil or natural gas, electric furnace easier to control, resulting in less pollution, and can prevent the kind of volatile substances borides from molten glass evaporate. In addition, electric melting process significantly reduces heat loss, the glass itself is more pure and homogeneous.

The melting point of molybdenum 2617 ℃, with which it has good electrical conductivity and thermal conductivity and thermal expansion coefficient is relatively small, so it is most suitable for molten glass electrode material. Molybdenum molten glass corrosion resistance strong, it made of glass melting electrodes, 1 ~ 3A/cm2 can withstand high current loads. However, in order to avoid oxidation loss, molybdenum electrode surface shall always be covered with a layer of molten glass. Retaining the glass melt, the molybdenum and some other uses, such as a thermocouple housing, a stirrer, stopper and a gas diffuser.

Drawn glass quartz device

As early as 1940, the German chemist drawing on the successful development of continuous quartz glass tube equipment. Modern manufacturer much larger scale than the original, but the structure is basically the same principle.

High quality quartz glass tube drawn to a low viscosity quartz, quartz therefore must be kept at a treatment temperature of about 1950 ℃. Molybdenum and tungsten are the only increase in the melting pot suitable for the manufacture, die, core material and the heating element. Protective atmosphere to prevent oxidation is essential.

Typical crucible diameter up to 350mm, length 1300mm, with a variety of designs, including pressing and sintering of molybdenum thick-site disaster. Thin wall collapse can increase, which is a plate made from a single piece, the inner layer of tungsten plate, the outer layer of molybdenum plate.

Ceramic fiber production equipment

In many applications require insulating material, the ceramic fiber products have replaced the asbestos material. As heat insulation, sound insulation, ceramic fiber is widely used in posture construction industry. Also used in the cold fireplace and hot isostatic pressing device.

Ceramic fibers in a large tank furnace, a molten mixture of alumina and kaolin produced by means of a molybdenum electrode immersed electrofusion, electrofusion is substantially the same as the glass, but higher melting temperature ceramic, up to about 2030 ℃ . Molybdenum cylindrical electrode diameter 75 ~ 100mm, length up to 360mm. In addition, a diameter of about 15 ~ 20mm using a molybdenum rod as "needle", to control the nozzle after melting ceramic molybdenum traffic.

If you have any interest in our molybdenum alloy or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.