Doping methods impact on molybdenum composite billet microstructure as follow:

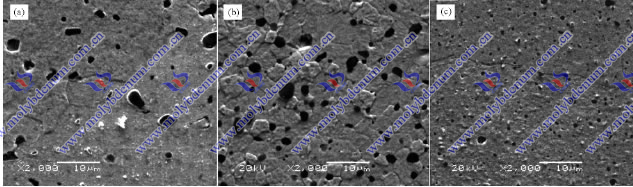

The following figure shows the same doping (φAl2O3 = 10%) were under way by the three kinds of doped molybdenum blanks prepared composite SEM photograph, the figure is tiny black particles Al2O3 particles.

The figure shows:

Solid - Solid doped molybdenum final resultant composite billet Al2O3 particles coarser, and the size is inconsistent, in the uneven distribution of molybdenum matrix;

Solid - liquid doping and solid - solid doping compared resultant composite billet Al2O3 particles of molybdenum has been reduced, and the distribution is more uniform;

Liquid - liquid doped molybdenum compound obtained preform, Al2O3 particles most most small and relatively uniform, but the density distribution along the grain boundary is higher.

Pic. 10% Al2O3 Doped Molybdenum composite Billet SEM Microstructure Photograph

From the above figure shows, doping also affected the second phase that the Al2O3 in the composite particle size and uniform distribution of molybdenum of the preform. Al2O3 particles in the form of dots are dispersed in the molybdenum matrix, mainly located around the hole in the grain boundary and the sintering, no cracks, no gaps, with no significant mutual diffusion at the transition, a good combination with a molybdenum substrate.

Three different modes doped Al2O3 particle size is also very different. Doped molybdenum powder with Al2O3 particles compared to the Al2O3 doped molybdenum billet diameter increased, indicating that the Al2O3 particles during sintering molybdenum substrate in refinement, while also continue to grow their own, and through the sintered Al2O3 and molybdenum matrix closely. Liquid - liquid dopant is essentially the grain boundary and the second phase to control the grain growth of molybdenum, stabilize the grain size within a certain range, and molybdenum grain size has a direct impact on the uniform distribution of dopant oxide sex.

If you have any interest in our molybdenum composite billet other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.