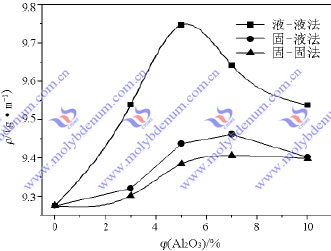

Doping methods impact on molybdenum composite material density as follow:

Below is prepared with different doping methods Al2O3/Mo Al2O3 composite doping density with the curve.

As can be seen from this graph:

Doping under the same liquid - liquid dopant maximum density of the obtained composite material, the solid - liquid doped second, solid - solid doped minimum;

With Al2O3 doping increases, the three ways the density of the prepared composites showed increases first and then decreases the law.

This shows that the overall densification of the material Al2O3 play a role, but small Al2O3 density than Mo, when Al2O3 doped reaches a certain value, causing densification increases the density will be less than the increase in volume caused by Al2O3 reduced density , but the bulk density of the material tends to decrease.

Fig. Density of the Composite Curve Al2O3/Mo

If you have any interest in our molybdenum composite material other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.