Molybdenum alloy single crystal preparation as follows:

Preparation of raw seed selection → seeded electron beam zone melting crystal orientation → Preparation → Performance Test

1. Choice of raw materials

Molybdenum alloy single crystal preparation generally used secondary electron bombardment of an ingot forging molybdenum rod.

(2) Preparation of seed

Seed electron beam zone melting method developed into the natural growth of single crystals by X-ray examination directional cut. Process is as follows:

Electron beam zone melting method nurture natural growth of single crystal orientation test → X-ray cut seed grinding → polishing → X optical directional etching reinspection → seed.

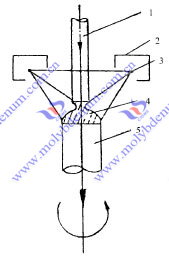

Pic. zone melting crystal growth schematic packing method

1.raw bar; 2.two focus coils; 3.electron gun;

4.melted heap; 5.crystal growth

(1) Single crystal orientation test. Natural single crystal H2SO4: HNO3: HF = 5:2:2 (volume ratio) was corrosion, macroscopic examination, and examination by X-ray single crystal and the orientation of Laue xerography.

(2) The seed crystal cut. A seed crystal is preferably cut wire cutting, machining method can also be used. The cut surface of seeds Jingjing average error of 2.2 °, 6.5 ° seeds Jingjing surface deviation less, and both were directed to meet the requirements of molybdenum single crystal surface. Growing seeds Jingjing surface error control and adjustment error can be controlled at about 1 °.

(3) The seed crystal condition. Seed shape requirements normalized diameter close to the sample size, the seed surface oxidation is not serious, should not be too thick worse, not mechanical damage layer, etc., have been cut seed still grinding, polishing and deep corrosion to remove mechanical damage layer etching method with dark seed is not verified before it is used to shred seeded.

3. Seeding

In order to obtain a good state of the molten zone, to improve the efficiency of seeding, to ensure that the electron gun when loading, the focus of the three concentric cover and base. And must be strictly perpendicular to the axis of the specimen seed Jingjing surface. With the sample size becomes small, the electron gun, the focus diameter of the cover and the base plate should be correspondingly smaller, narrower melting zone, it is a good seeding.

If you have any interest in our molybdenum alloy single crystal or other molybdenum alloy products, please feel free to contact us by email: sales@chinatungsten.com,sales@xiamentungsten.com or by telephone:86 592 512 9696.